GRP (Glass Reinforced Plastic) pipe seals, also known as fiberglass pipe seals or gasket seals, are specialized sealing components designed for use in fiberglass reinforced plastic piping systems. These seals play a crucial role in ensuring the integrity and leak-proof performance of GRP pipes, which are commonly used in various industries, including chemical processing, water treatment, wastewater management, and oil and gas transportation. In this comprehensive description, we will explore the key aspects of GRP pipe seals, including their composition, functions, installation methods, advantages, and applications.

Composition:

GRP pipe seals are typically composed of high-quality materials to provide excellent sealing properties and long-lasting performance. The key components of these seals may include:

- Elastomeric Materials: The sealing element of a GRP pipe seal is often made from elastomeric materials like EPDM (Ethylene Propylene Diene Monomer) rubber, Nitrile rubber, or Viton. These materials offer resilience, chemical resistance, and flexibility, allowing the seal to adapt to varying pipe joint conditions.

- Reinforcement Layers: To enhance the strength and durability of the seal, reinforcement layers may be incorporated. This can include textile or fabric layers embedded within the elastomeric material.

- Flange or Collar: Some GRP pipe seals feature flanges or collars made from materials like stainless steel or galvanized steel. These components provide structural support and ensure a secure fit within the pipe joint.

Functions:

GRP pipe seals serve several critical functions within a piping system:

- Sealing: The primary function of these seals is to create a reliable and leak-free joint between two sections of GRP pipes or between a GRP pipe and other connecting elements, such as valves or fittings.

- Compensation for Movement: GRP pipes can experience thermal expansion, contraction, and settling over time. The flexibility of the elastomeric seal allows it to accommodate these movements, maintaining a tight seal.

- Chemical Resistance: The choice of elastomeric material ensures resistance to various chemicals and fluids that may flow through the pipes, preventing degradation or deterioration of the seal.

Installation Methods:

The installation of GRP pipe seals typically involves the following steps:

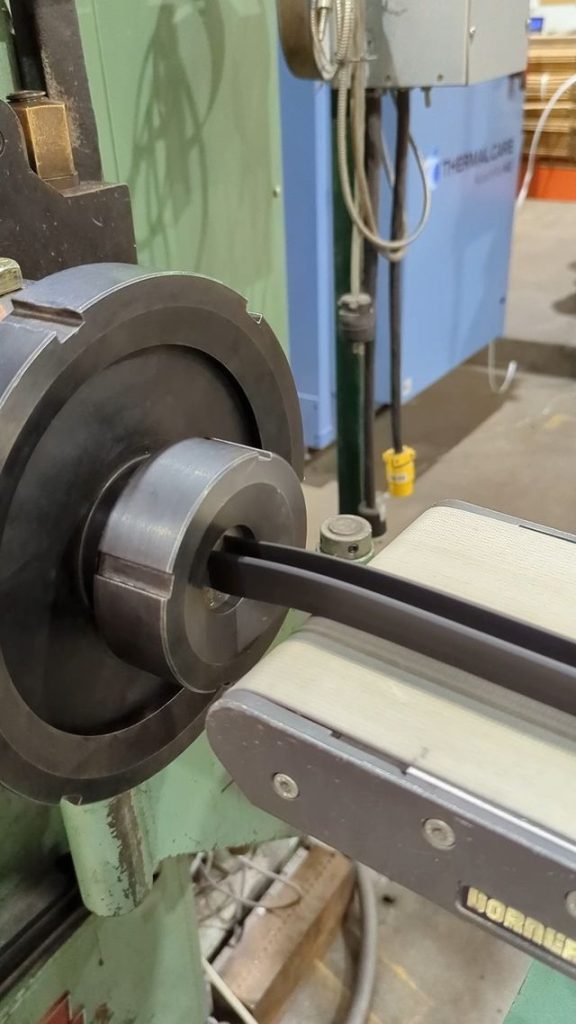

- Surface Preparation: Ensure that the pipe ends are clean, dry, and free from debris or contaminants. Proper surface preparation is crucial for a secure seal.

- Apply Lubricant: Lubricate the seal and the pipe joint to ease installation and reduce friction during compression.

- Position the Seal: Place the GRP pipe seal evenly over the joint area, ensuring it is centered and correctly aligned.

- Tighten Flanges or Collars: If the seal includes flanges or collars, tighten them gradually and evenly in a crisscross pattern to compress the seal and create a secure connection.

- Inspect and Test: Conduct a visual inspection to ensure the seal is correctly installed and free from visible defects. Pressure or leak tests may be performed to verify the seal’s integrity.

Advantages:

GRP pipe seals offer several advantages in piping systems:

- Leak Prevention: They provide a reliable and long-lasting seal, minimizing the risk of leaks and fluid loss.

- Chemical Resistance: GRP pipe seals are resistant to a wide range of chemicals and aggressive fluids, ensuring compatibility with various industrial applications.

- Flexibility: Their elastomeric nature allows them to accommodate movement and vibration, maintaining a secure seal over time.

- Durability: These seals are designed for long-term performance and can withstand harsh environmental conditions.

- Easy Installation: The installation process is straightforward and can be carried out with basic tools and equipment.

Applications:

GRP pipe seals are used in a variety of industrial applications, including:

- Chemical Processing: To seal joints in GRP pipes used for transporting corrosive chemicals.

- Water and Wastewater Treatment: In municipal water treatment facilities and wastewater management systems.

- Oil and Gas Industry: For piping systems in offshore platforms, refineries, and petrochemical plants.

- Infrastructure: In infrastructure projects such as bridges, tunnels, and culverts, where GRP pipes are used for drainage and sewage systems.

- Marine and Shipbuilding: In marine applications, including ship pipelines and offshore installations.

In summary, GRP pipe seals are essential components in fiberglass reinforced plastic piping systems, ensuring the integrity, leak resistance, and long-term performance of these systems in a wide range of industrial and environmental settings. Their versatility, chemical resistance, and ability to accommodate movement make them a critical element in ensuring the safe and efficient transportation of fluids in various industries. Proper installation and maintenance are essential to maximize the effectiveness of GRP pipe seals in any application.