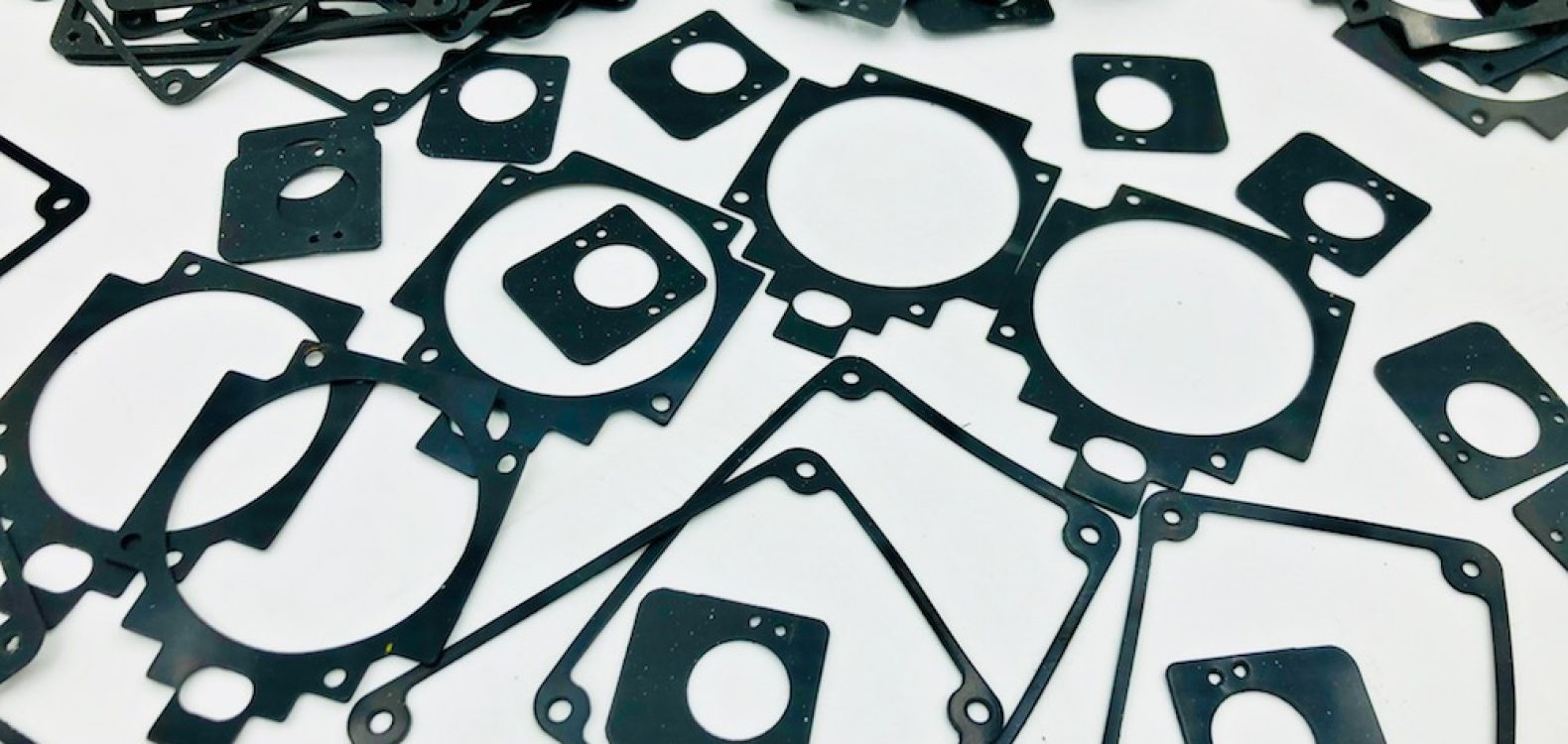

A factory that specializes in the production of EPDM gaskets is a sophisticated manufacturing facility designed to produce high-quality gaskets made from Ethylene Propylene Diene Monomer (EPDM) rubber. This detailed description will provide insights into the key aspects of such a factory, including its infrastructure, manufacturing processes, quality control measures, and the importance of adhering to industry standards.

Infrastructure and Layout:

- Raw Material Storage: The factory begins with a well-organized raw material storage area where EPDM rubber compounds, along with other additives and ingredients, are kept in controlled environments to maintain their quality.

- Mixing and Compounding Area: EPDM gasket production starts with the mixing and compounding of the rubber. This area houses large mixing machines where EPDM rubber is blended with various ingredients to achieve the desired properties, such as hardness, resilience, and chemical resistance.

- Extrusion and Molding: After compounding, the rubber is processed through extrusion machines or molds to create gasket profiles of different shapes and sizes. The factory typically features a range of molds and dies to cater to diverse customer needs.

- Vulcanization Chambers: Vulcanization, a critical step in EPDM gasket manufacturing, involves subjecting the molded gaskets to heat and pressure in vulcanization chambers or autoclaves. This process cures the rubber, enhancing its durability and resistance properties.

- Secondary Processing: Some gaskets may require secondary processes such as cutting, punching, or adhesive application. Specialized equipment is employed for these tasks.

- Quality Control and Testing Labs: Throughout the production process, quality control is paramount. The factory includes dedicated labs equipped with testing instruments to ensure that gaskets meet stringent quality standards. This includes tests for hardness, tensile strength, compression set, and chemical resistance.

Manufacturing Processes:

- Compound Preparation: The EPDM rubber compound is carefully prepared, incorporating the necessary ingredients to achieve the desired properties, including hardness and chemical resistance.

- Extrusion or Molding: Depending on the gasket’s design, EPDM material is either extruded through dies or molded into specific shapes.

- Vulcanization: The molded gaskets are then cured in vulcanization chambers, where they undergo the vulcanization process, resulting in the cross-linking of polymer chains and the enhancement of their physical properties.

- Finishing and Inspection: After curing, gaskets undergo finishing processes like trimming, cutting, or adhesive application. Each gasket is meticulously inspected for defects and dimensional accuracy.

Quality Control Measures:

- Material Traceability: The factory maintains strict control over raw materials, ensuring that each batch of EPDM rubber meets the required specifications and is traceable to its source.

- In-Process Inspections: Quality control personnel perform regular checks during the manufacturing process to identify and rectify any issues that may arise.

- Testing Protocols: Comprehensive testing protocols are established to verify that gaskets meet industry standards and customer specifications. This includes tests for physical properties, chemical resistance, and adherence to temperature and pressure ratings.

- Documentation: Detailed records of production processes, materials used, and quality test results are maintained to track and ensure the consistency and quality of gaskets.

Industry Standards and Compliance:

An EPDM gasket factory adheres to industry-specific standards and regulations, such as ASTM (American Society for Testing and Materials) standards, to guarantee the reliability and performance of its products. Compliance with these standards ensures that gaskets can safely and effectively perform their sealing functions in various applications.

In conclusion, an EPDM gasket factory is a highly specialized manufacturing facility equipped with state-of-the-art machinery and quality control measures to produce EPDM gaskets of exceptional quality and reliability. It operates with precision and adherence to industry standards, ensuring that the gaskets it produces meet the stringent requirements of diverse industries and applications.