Concrete pipe seals, also known as pipe gaskets or concrete pipe joint seals, are specialized components used to create watertight and secure connections between concrete pipes in various applications, including sewage systems, stormwater drainage, culverts, and other infrastructure projects. These seals are crucial for preventing water infiltration, maintaining pipe integrity, and ensuring the durability and effectiveness of the overall piping system. Here are key aspects of concrete pipe seals:

Types of Concrete Pipe Seals:

- Rubber Ring Seals: Rubber ring seals are one of the most common types of concrete pipe seals. They consist of a circular elastomeric ring made from materials like EPDM (Ethylene Propylene Diene Monomer) rubber, neoprene, or nitrile rubber. These rings are inserted into a groove or recess within the pipe socket, creating a compression seal when the pipes are joined.

- Single Offset Joint Seals: Single offset joint seals are used in concrete pipes with a bell and spigot configuration. They consist of a rubber gasket that is placed in the bell end of one pipe to create a seal with the spigot end of another pipe when they are connected.

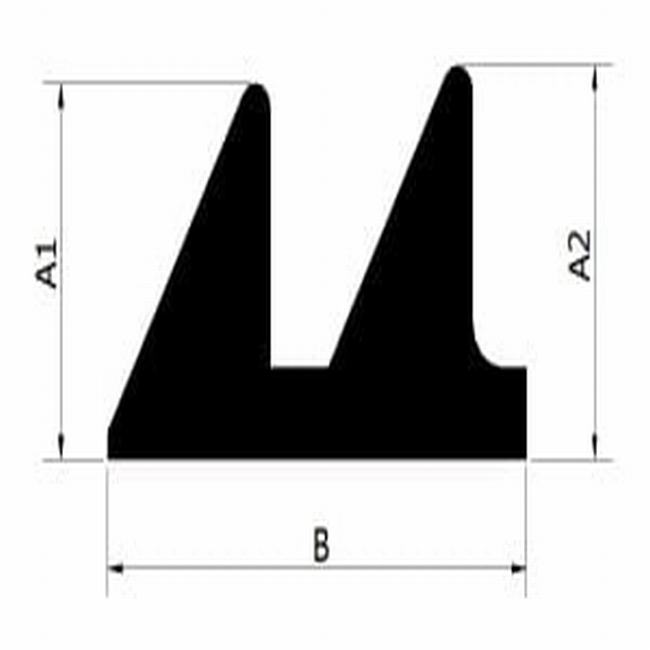

- Double Offset Joint Seals: Double offset joint seals are similar to single offset seals but are designed for concrete pipes with an added offset feature. They create a secure seal when the offset sections of the pipes are joined.

- O-Ring Seals: O-ring seals are circular rubber gaskets with a cross-sectional shape resembling the letter “O.” They are placed in the joint or groove of concrete pipes to create a sealing effect when pipes are connected.

Functions:

The primary functions of concrete pipe seals include:

- Water Tightness: Concrete pipe seals create a watertight seal between pipe sections, preventing the infiltration of groundwater, soil, and other external elements into the pipe system.

- Structural Integrity: Seals help maintain the structural integrity of the pipe system by preventing joint separation, displacement, or failure.

- Chemical Resistance: Some seals are designed to resist chemical exposure, making them suitable for use in aggressive environments or where chemical resistance is required.

Installation:

Installing concrete pipe seals typically involves the following steps:

- Clean Surfaces: Ensure that the mating surfaces of the pipes are clean, free of debris, and dry.

- Inspect Seals: Check the condition and quality of the seals before installation to ensure they are free of defects or damage.

- Apply Lubricant: Apply a suitable lubricant to the seals to facilitate their insertion and ensure a proper fit.

- Insert Seals: Carefully insert the seals into the grooves or recesses of the pipe sockets, ensuring they are properly seated and aligned.

- Join Pipes: Connect the concrete pipes by aligning the spigot end with the bell end and pushing or twisting them together to engage the seal.

- Check Alignment: Ensure that the pipes are correctly aligned, and the seal is properly compressed.

Maintenance:

Regular inspection and maintenance of concrete pipe seals are essential for ensuring their ongoing effectiveness. Inspect the seals for signs of wear, damage, or deterioration, and replace any seals that are no longer in good condition.

In summary, concrete pipe seals are critical components in various infrastructure projects, providing watertight and secure connections between concrete pipes. Proper selection, installation, and maintenance of these seals are essential for the long-term performance and durability of concrete pipe systems in sewage, drainage, and other applications.